Imagine a world where maintenance issues are resolved before they even become problems. With the integration of Business Process Management (BPM) and predictive analytics, this is not just possible but also incredibly efficient. Predictive analytics makes use of historical and current data to forecast potential issues, while BPM brings order and efficiency to the process. Together, they revolutionize equipment maintenance.

The Power of Predictive Analytics

With predictive analytics, you can anticipate equipment failures and schedule maintenance proactively. It uses data, statistical algorithms, and machine learning techniques to predict future outcomes based on historical data. The goal is to go beyond knowing what has happened to providing a best assessment of what will happen in the future. This enables businesses to act proactively, reducing equipment downtime and saving costs.

However, predictive analytics alone is not enough. While it can forecast potential issues, you need an effective way to manage these predictions. That’s where BPM comes in.

BPM is the practice of aligning goals, procedures, and communication to improve and streamline business processes. It ensures that the right people are in the right place, with the right tools at the right time. Combined with predictive analytics, BPM can help businesses revolutionize their equipment maintenance procedures.

The Role of BPM Analytics in Predictive Maintenance

When it comes to harnessing bpm analytics for predictive maintenance, it is crucial to understand the interplay between data analysis and process management. BPM analytics delve into the performance of business processes, analyzing data to identify patterns and trends that can lead to process improvement. In the context of equipment maintenance, bpm analytics can highlight inefficiencies in maintenance schedules, predict the optimal timing for maintenance, and thus prevent unplanned downtime.

Integrating BPM with Predictive Analytics

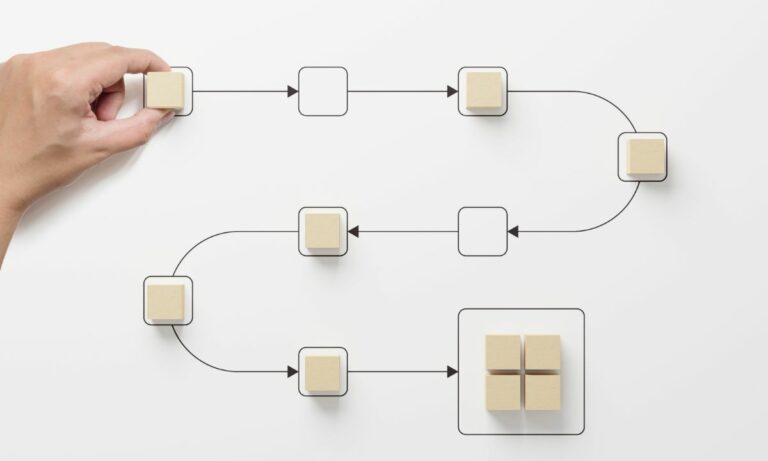

Integrating BPM and predictive analytics for equipment maintenance involves creating workflows that can interpret predictive data and trigger appropriate actions. For example, if predictive analytics indicates that a particular piece of equipment is likely to fail in the next month, the BPM system can initiate a maintenance process. This could include notifying the maintenance team, scheduling a service, ordering necessary parts, and even informing the finance department about the expected costs.

Moreover, BPM ensures that no steps are missed and that each process is carried out efficiently and effectively. It provides a clear, visual representation of workflows, making it easier to identify bottlenecks and optimize processes. This means you can not only predict equipment failures but also manage them efficiently when they happen.

By integrating predictive analytics with BPM, businesses can move from reactive to proactive maintenance. This not only saves money but also improves operational efficiency and prolongs the life of equipment. It’s a powerful way to revolutionize your equipment maintenance processes.

BPM and Predictive Analytics with Flokzu

Flokzu offers a robust BPM solution that can be integrated with predictive analytics to revolutionize your equipment maintenance. With Flokzu, you can easily design and automate workflows based on predictive data. Whether it’s scheduling maintenance, ordering parts, or managing costs, Flokzu can help you streamline these processes and ensure they’re carried out effectively.

Moreover, Flokzu offers affordable pricing options to suit businesses of all sizes. Whether you’re a small business just starting with BPM or a large organization looking to optimize your processes, Flokzu has a solution that suits your needs.

Ultimately, the integration of BPM and predictive analytics is a game-changer for equipment maintenance. It enables businesses to be proactive, reduce costs, and improve efficiency. And with a BPM solution like Flokzu, implementing this integration is easier than you might think.

Ready to revolutionize your equipment maintenance? Schedule a free demo of Flokzu and see how you can unleash the power of BPM and predictive analytics in your business.