Lean manufacturing has been a pivotal approach in the industry for decades. This method, originally developed by Toyota, focuses on minimizing waste within manufacturing systems while simultaneously improving productivity. However, as the business landscape becomes more complex, companies are seeking ways to optimize lean manufacturing even further. This is where Business Process Management (BPM) steps in. BPM can revolutionize lean manufacturing, making it more efficient, flexible, and adaptable to changes.

The Symbiosis of Lean Manufacturing and BPM

The principles of lean manufacturing and BPM go hand in hand. Both methodologies focus on reducing waste, improving efficiency, and delivering value to customers. While lean manufacturing emphasizes the physical production process, BPM extends this perspective to encompass all business processes, making it a holistic approach to business efficiency.

By integrating BPM into lean manufacturing, businesses can achieve a deeper level of process optimization. This fusion enables companies to identify bottlenecks, implement improvements, and monitor results in real-time. In addition, BPM tools offer automation capabilities, freeing up employee time to focus on more value-adding tasks.

Furthermore, the adaptability of BPM tools allows businesses to quickly respond to changes. Whether it’s a change in demand, a new regulation, or an internal restructuring, a BPM-enabled lean manufacturing process can adjust swiftly and efficiently. This level of agility is crucial in today’s fast-paced, dynamic business environment.

The Role of BPM Tools in Lean Manufacturing

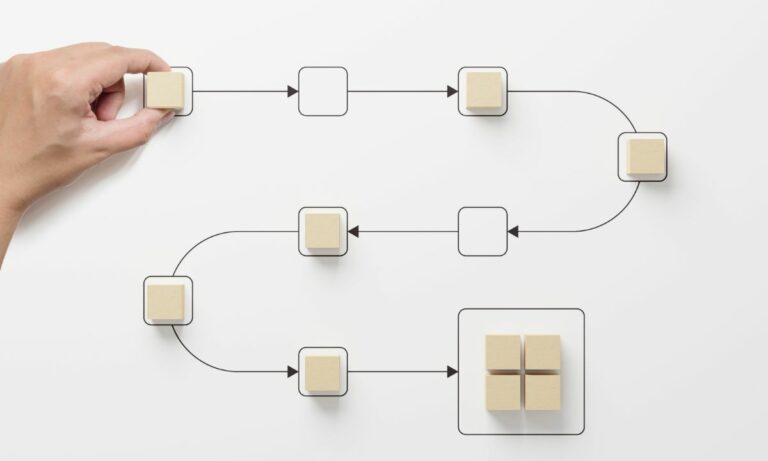

The functionality of BPM tools is diverse and impactful, particularly when applied to lean manufacturing. One of the most significant benefits is the ability to map and model processes. This feature provides a visual representation of your processes, making it easier to identify inefficiencies and areas for improvement.

Once you’ve mapped your processes, you can begin automating repetitive tasks. This not only accelerates the process but also reduces the chance of human error. Moreover, automated processes are easier to monitor, allowing for real-time data collection and analysis. This data-driven approach enables continuous improvement, a cornerstone of lean manufacturing.

Another crucial aspect of BPM tools is their ability to foster collaboration. By providing a shared platform, BPM tools encourage cross-departmental collaboration, leading to more innovative solutions and a stronger alignment towards common goals. In a lean manufacturing environment, this collaboration is vital for maintaining a continuous improvement culture.

Flokzu: Your Partner in Lean Manufacturing Optimization

Choosing the right BPM tool is essential for optimizing lean manufacturing. Here at Flokzu, we offer a comprehensive BPM solution that is intuitive, flexible, and adaptable. Our tool enables you to map, automate, and monitor your processes with ease, resulting in significant efficiency gains.

Moreover, we understand that every business is unique. That’s why Flokzu is fully customizable to meet your specific needs. Whether you want to automate a single process or transform your entire business model, Flokzu is designed to scale with your business.

Our pricing plans are designed to provide maximum value, regardless of your business size or industry. With Flokzu, you can begin your journey towards lean manufacturing optimization without breaking the bank.

The Future of Lean Manufacturing

The integration of BPM into lean manufacturing is not just a trend; it’s the future. As we move towards a more digital, interconnected world, the ability to optimize and adapt processes will become increasingly crucial. By leveraging BPM, businesses can stay ahead of the curve and maintain their competitive edge.

Furthermore, as artificial intelligence and machine learning continue to evolve, the potential of BPM will only grow. These technologies can enhance BPM tools, enabling more advanced automation and predictive analytics. As such, the role of BPM in lean manufacturing will continue to grow and evolve.

Ultimately, the future of lean manufacturing lies in the fusion of traditional lean principles with modern BPM tools. This combination creates a robust, adaptable framework that can drive business success in the digital age.

We at Flokzu are excited to be part of this revolution. Our BPM tool is designed to help businesses optimize their processes and embrace the future of lean manufacturing. So why wait? Take the first step towards lean manufacturing optimization. Automate your first process for free with Flokzu today.