Business Process Management (BPM) is a potent tool for companies looking to improve their operational efficiency. It’s especially critical in the realm of manufacturing, where automated assembly lines are a staple. By using BPM, companies can revolutionize how they coordinate these assembly lines, leading to increased productivity and reduced costs. But how does this transformation occur? Let’s delve into this mystery and see how BPM transforms the coordination of automated assembly lines.

Understanding BPM and Automated Assembly Lines

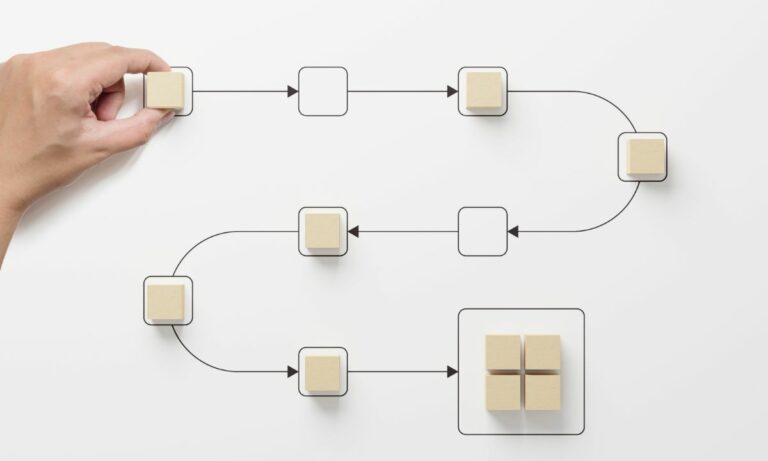

Before we explore the impact of BPM on automated assembly lines, it’s essential to understand these two elements. Business process management is an approach that involves managing, controlling, and improving business processes. It aims to enhance the effectiveness and efficiency of these processes while offering flexibility for future changes.

On the other hand, an automated assembly line is a sequential production process where the parts are usually added in a specific, repeated order. It’s integral to mass production, and its efficiency is a significant factor in a company’s productivity and profitability.

Now that we’ve established what BPM and automated assembly lines are, we can begin to see how the former can transform the coordination of the latter.

The Integration of BPM in Automated Assembly Lines

Integrating BPM into automated assembly lines can be a game-changer. BPM software, like the one Flokzu offers, allows for process automation, which can significantly enhance the coordination of assembly lines. This integration can lead to several key transformations.

Firstly, it allows for real-time monitoring of assembly lines. With BPM, managers can track the progress of the assembly process, identify bottlenecks, and make necessary adjustments on the fly. This real-time monitoring can lead to a more efficient assembly process and improved product quality.

Secondly, BPM integration can lead to better data management. With automated data collection and analysis, companies can gain valuable insights about their assembly process. This information can then be used to make data-driven decisions and continuous improvements.

Transforming Coordination with BPM

Coordination is key in running an efficient automated assembly line. With BPM, the coordination of these assembly lines can be transformed in several ways.

One key transformation is improved communication. BPM software allows for seamless communication between different parts of the assembly line, ensuring that all components work together harmoniously. This improved communication can lead to fewer errors and a smoother production process.

Another transformation is the automation of routine tasks. BPM software can automate tasks such as scheduling, monitoring, and reporting, freeing up employees to focus on more critical tasks. This automation can lead to improved efficiency and productivity.

In conclusion, BPM can indeed transform the coordination of automated assembly lines, leading to various benefits like improved efficiency, better communication, and enhanced decision-making. Schedule a free demo of Flokzu today and start your journey towards improved business process management.