Manufacturing businesses worldwide are continually seeking ways to optimize their processes for better productivity and cost-efficiency. In recent years, significant advancements in technology have given rise to transformative solutions like collaborative robotics and Business Process Management (BPM). This article will delve into how these game-changing technologies can revolutionize your manufacturing operations.

Understanding Collaborative Robotics

Collaborative robots, often referred to as “cobots”, are designed to work hand-in-hand with human employees. Unlike traditional robots that operate in isolation, cobots are built to interact with people in a shared workspace. This capability significantly enhances safety and efficiency.

These robots can perform repetitive tasks with high precision and speed, reducing the risk of human error. Moreover, they help free up your staff, enabling them to focus on more complex tasks that require human intellect and creativity.

Integrating cobots into your manufacturing process can lead to increased productivity, quality, and accuracy. However, to maximize their potential, it’s crucial to pair them with effective BPM.

Leveraging Business Process Management (BPM)

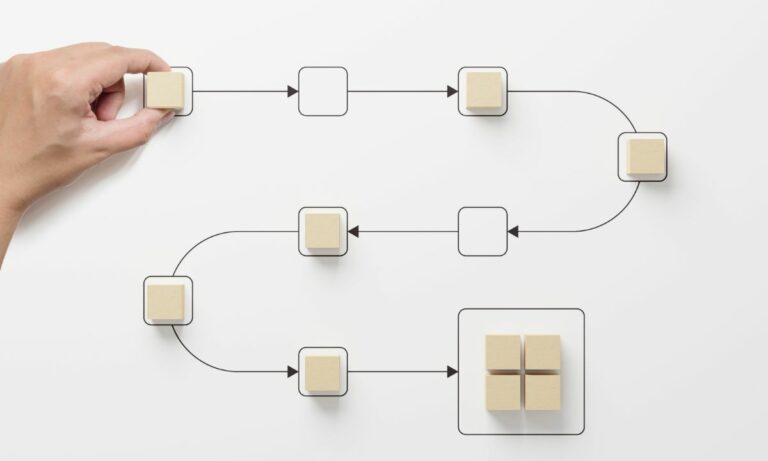

BPM is a systematic approach to making an organization’s workflow more effective, efficient, and adaptable. It involves designing, modeling, executing, monitoring, and optimizing business processes. Through BPM, businesses can have a clear picture of their processes, identify bottlenecks, and implement necessary improvements.

When combined with collaborative robotics, BPM can further streamline operations, leading to improved productivity and efficiency. BPM software, like Flokzu, can help manage these processes effectively. It provides a platform for automating tasks and workflows, leading to a more organized, transparent, and efficient working environment.

One of the significant advantages of BPM is its ability to adapt to changes quickly. It allows for quick modifications in the process or strategy, which is crucial in today’s fast-paced manufacturing industry.

The Synergy of Cobots and BPM

When collaborative robotics and BPM are combined, they create a powerful synergy that can significantly enhance manufacturing operations. Cobots perform tasks with high precision and consistency, while BPM ensures these tasks align with the organization’s overall workflow and objectives.

Moreover, this combination allows for real-time monitoring and analysis of operations. With BPM software like Flokzu, businesses can gather data from cobots, analyze it, and gain insights to improve their processes. This data-driven approach leads to continuous improvement and optimization.

When you utilize the power of cobots and BPM, you’re not only improving your current operations but also equipping your business to adapt to future changes and challenges.

Conclusion: Embrace the Future with Flokzu

Embracing collaborative robotics and BPM is no longer a futuristic concept, but a competitive necessity. As a manufacturing business, optimizing your processes with these technologies will not only boost your productivity and efficiency but also enhance your adaptability in an ever-changing industry.

With Flokzu’s robust BPM solution, you can automate your workflows, enhance collaboration, and drive continuous improvement. You can check out their various pricing plans to find one that best fits your needs.

Get started on your journey to process optimization. Schedule a free demo of Flokzu today and experience firsthand how it can transform your manufacturing operations.